GYS PROTIG 201 DC FV TIG Welder Package

Product Overview

-

The GYS PROTIG 200 DC FV TIG is an industrial inverter designed with advanced technology electronics to provide exceptional performance and high-quality welds in both DC TIG & MMA welding modes. Thanks to the advanced secondary control system, it ensures optimum arc stability and constant current in all positions. Optimised TIG DC welding provides quality welds on all ferrous materials such as steel, stainless steel, titanium, and can also be used for welding copper and its alloys. Equipped with FV (flexible voltage), PFC (Power Factor Correction) technology and the addition of a powerful HF start enables the PROTIG 200 DC FV TIG welders to be run from input voltages of 85V up to 265V. It also means the machine can run well from a generator and copes well when being run off long extension leads or where mains power may be weak. The intuitive interface makes it incredibly simple to adjust the welding settings even whilst wearing TIG welding gauntlets.

Read more

Two modes of arc ignition, TIG DC HF start provides an easy & reliable non-contact method to create the arc, this helps to reduce the possibility of electrode contamination. The TIG DC Lift start mode is available for use in environments where the use of HF may be prohibited.

TIG DC pulse offers the benefits of decreased distortion due to lower heat inputs, higher deposition rates when welding out of position, stronger welds due to better fusion compared to non-pulse mode and lower level of fume. The Pulse frequency can be adjusted between 0.1 -2000kHz making it suitable for use on thin sheet material from 0.3mm.

Spot function makes it possible to minimise tacking times with fast, precise, and clean tack welds when joining thin sheets.

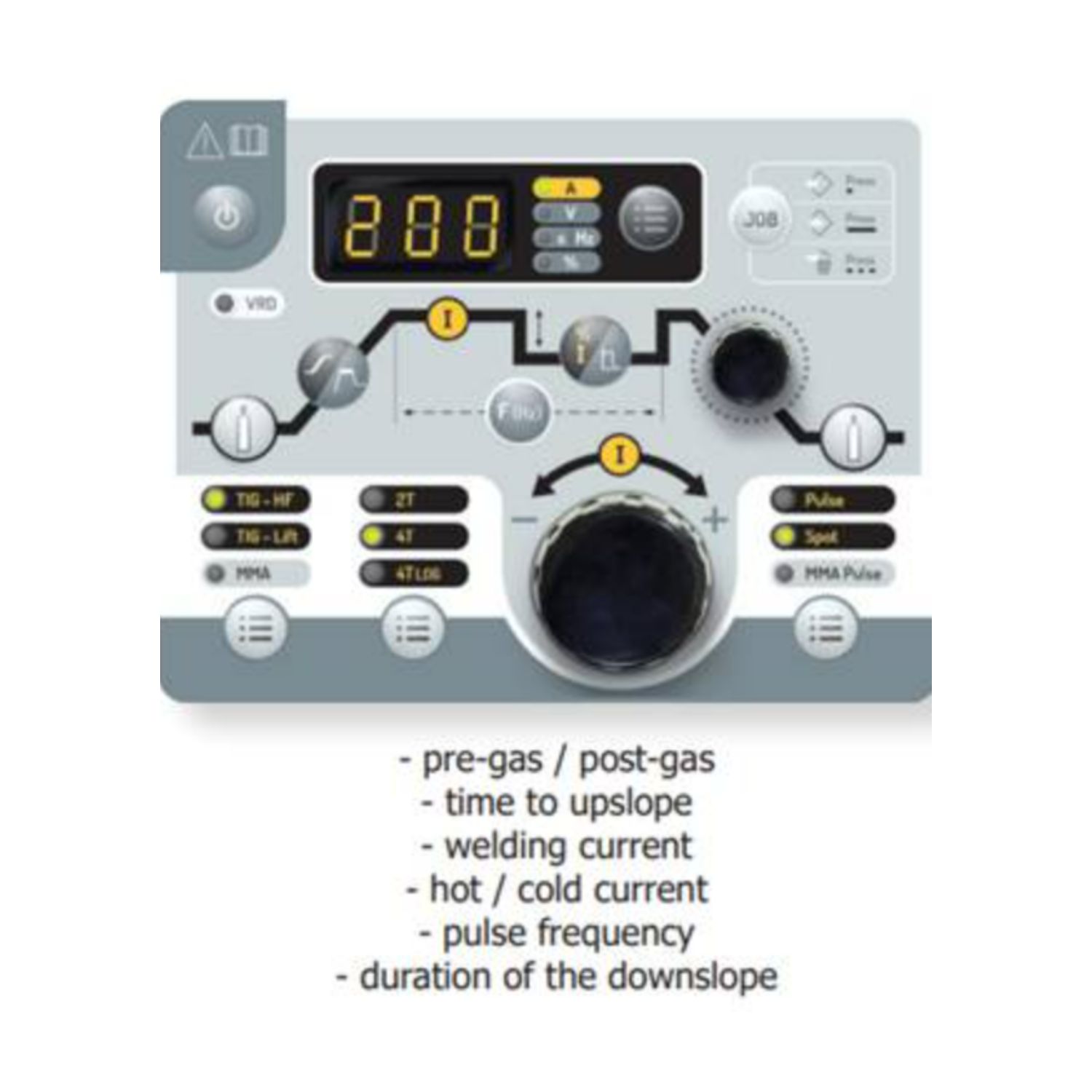

Advanced features include easy to use digital control panel allowing adjustment of all welding parameters such as pre- gas, upslope, pulse frequency, downslope & post-gas.

Three trigger torch controls: 2T, 4T and 4T LOG.

Automatic torch detection which is compatible with grip-handle and double-button torches.

The PROTIG 201 DC FV is also a fully functioning MMA machine with two MMA welding modes: MMA standard for welding with basic and rutile electrodes up to 5mm diameter. MMA adjustable Pulse helps to simplify welding in the vertical upright position and when pipeline welding.

Adjustable Hot Start is used to deliver a higher amperage when the electrode first comes into contact with the metal and can be adjusted in seconds according to the type of material. A lower Hot Start is used for thin metal sheets, whilst a higher Hot Start is better for metals which are more difficult to weld such as dirty or oxidized sheets.

Anti sticking helps to reduces the risk of the electrode sticking if it comes into contact with the workpiece.

Adjustable Arc force helps to ensure better penetration and prevention of the electrode sticking during the welding process.

VRD (Voltage Reduction Device) can be activated to lower the no-load voltage down to 35V when the welding machine is on, but not being used. This creates a safer environment when you’ve just finished an electrode and need to replace it with a new one. The VRD also provides added safety when operating Lift TIG mode to help ensure the welders safety prior to the arc being activated.

The easy to view display shows the current and voltage during and after the welding process for WPS (Welding Procedure Specifications) and PQR (Procedure Qualification Records) purposes.

Up to 50 different jobs can be stored in the machine for each process, ensuring perfect and consistent welds when producing repetitive tasks.

Intelligent ventilation management helps to reduce power consumption, reduces dust contamination and substation noise.

With its reinforced casing and anti-shock pads on each side of the machine makes the PROTIG 201 DC FV ideal for workshop or onsite usage.

Compact and light weight make it easy to move around the worksite.

PROTEC 400 technology protects against overvoltage up to 400 Volt.

Specification:

Amps range 240v – 16amp: MMA 10 – 200Amps.

TIG 10 - 200Amps.

Amps range 110v – 32amp: MMA 10 – 140Amps.

TIG 10 – 180Amps.

Pulse Frequency: 0.1 – 2000Hz

Duty cycle. EN 60974-1 (40°C): 240V MMA 60% @ 135Amp

TIG 60% @ 165Amp

Duty cycle. EN 60974-1 (40°C): 110V MMA 60% @ 100Amps

TIG 60% @ 125Amps

Input fuse. 16Amp (230V)

32Amp (110v)

Min generator size (+/- 15%) 6kw – 7.0Kva

Dimensions: 410 x 200 x 280mm

Approx. weight: 10.0kg

Supplied with:

Binzel SR26DB TIG Torch 4 meters long.

Box of Accessories for the SR17 & SR26 TIG Torch.

Electrode holder and cable 25 mm² x 2.0 meter long.

Earth Clamp and Cable 25 mm² x 2.0 meter long.